TM

55-1730-229-34

AG

320A0-MME-000

TO

35C2-3-473-2

TM

1730-34/1

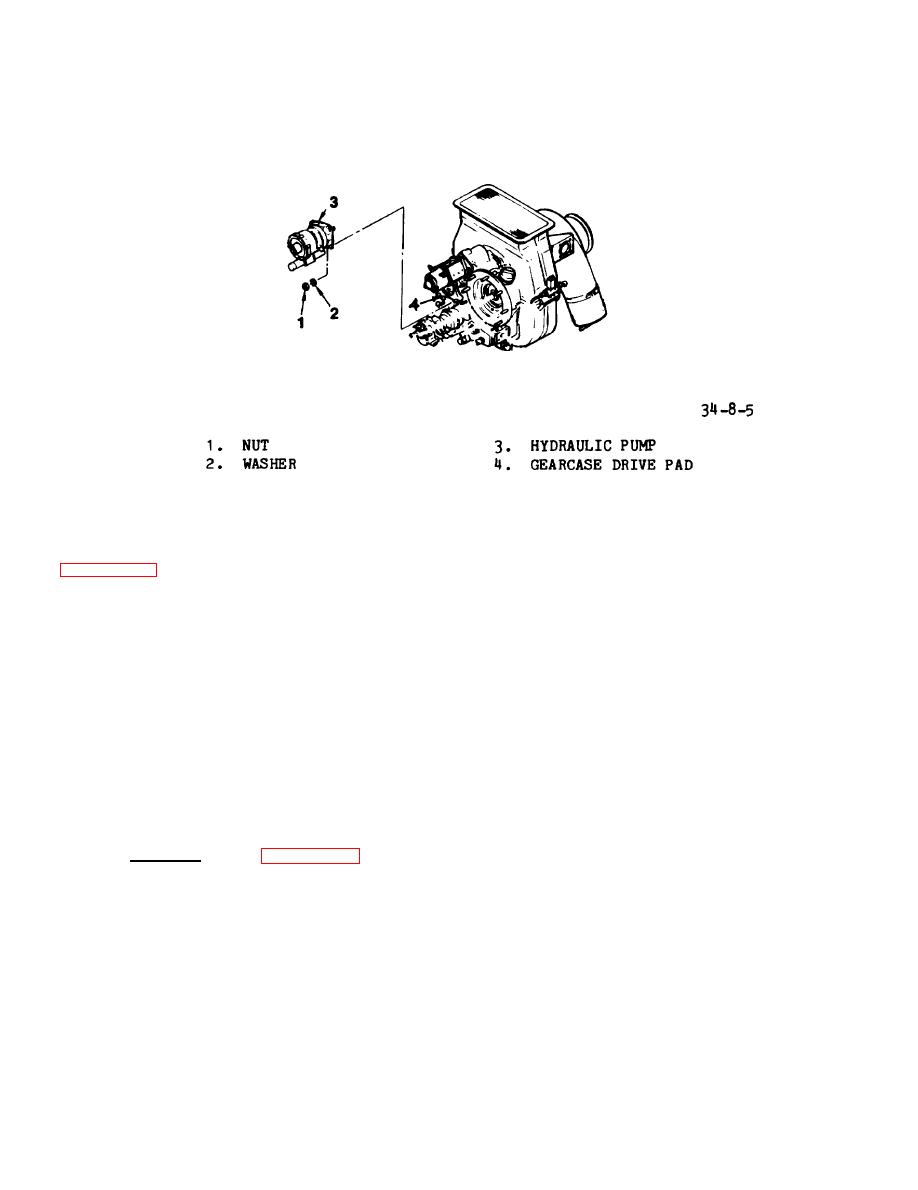

F i g u r e 8-5.

Hydraulic Pump Removal/Installation

( 6 ) Di s c o n n e c t h y d r a u l i c t u b e (1 9 ,

u p when elbow is within one turn of be-

f i g u r e 8-2) connector from elbow (9) o n

ing tight.

back of OUTPUT PRESSURE gauge (8). Re-

m o v e and discard copper seal (21).

( 4 ) Tighten elbow (9) with jam nut

(10).

(7) Remove bolts (6), nuts (7) and

standoffs (20).

(5) Insert gauge into hole in hy-

draulic control panel and secure with

( 8 ) Remove gauge (8).

bolts (6), nuts (7) and standoffs (20).

(6) Install a new 7C-4 copper seal

(9) Match mark elbow's (9) posi-

on elbow (9).

t i o n on back of gauge (8).

( 1 0 ) Loosen jam nut (10) and remove

(7) Fasten hydraulic tube connec-

e l b o w (9) from back of pressure gauge.

tor (19) to elbow (9).

Torque to be-

Remove jam nut (10).

tween 135 and 150 inch-pounds.

Install.

( S e e figure 8-2.)

b.

(8) Reinstall vent dryer as de-

s c r i b e d in paragraph 4-92, TM 55-1730-

229-12.

(1) Apply hydraulic fluid (MIL-H-

5606 or MIL-H-83282) to both sets of

t h r e a d s of elbow (9).

8-6. SIGHT GLASSES.

NOTE

(2) Install jam nut (10) on fit-

t i n g on back of gauge (8).

T h i s procedure does not require

(3) Screw elbow (9) onto gauge

that the module be removed from

Ensure that match marks are lined

(8).

the unit.

8-8