TM 55-1730-229-34

A 320A0-MME-000

TO 35 C2-3-473-2

TM 1730-34/1

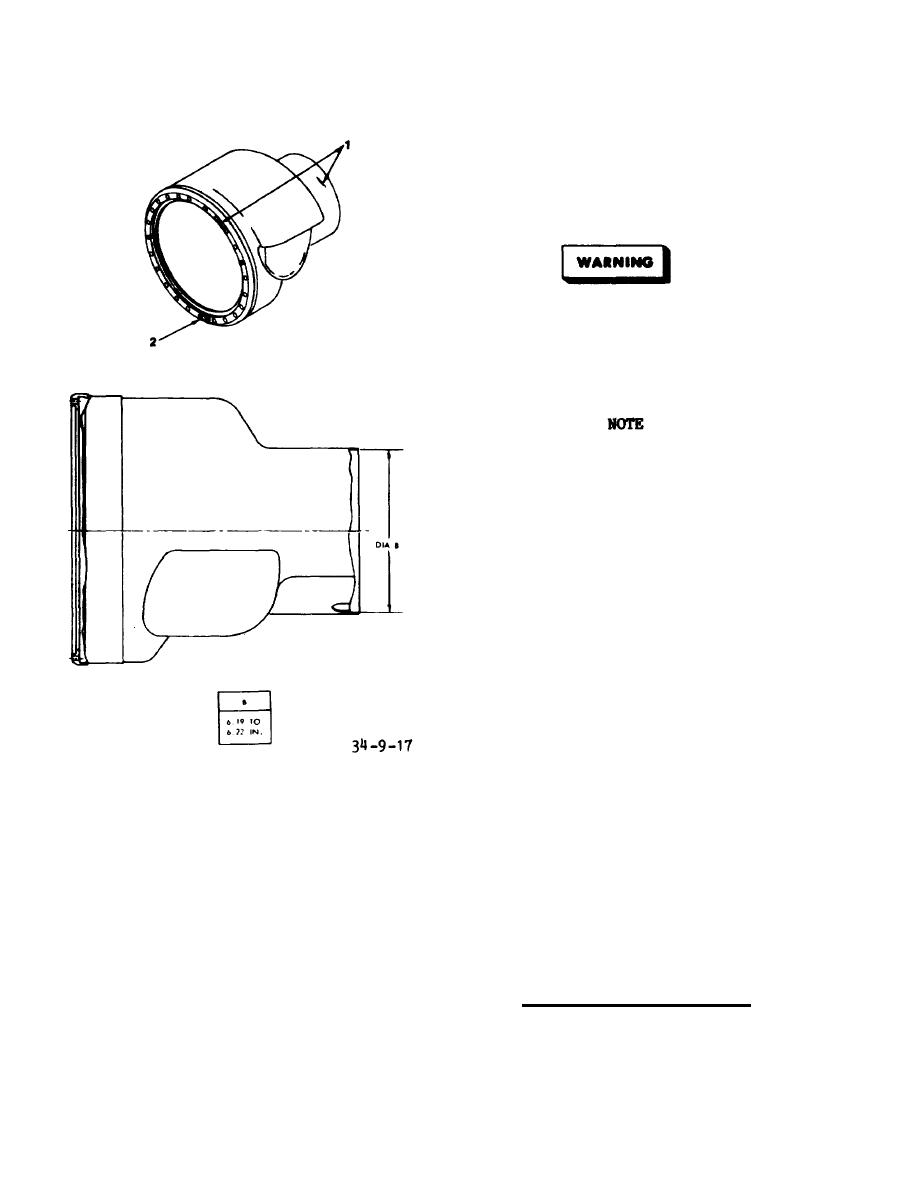

(2) Repair rub damage in inlet

flange as follows:

(a) Hand abrade to clean up

area.

Use solvent in a well-ventilated

area. Avoid excessive skin con-

tact or prolonged inhalation of

vapor. Do not use near open flame

or in area where high temperatures

prevail.

Compressed air shall be regulated

between 5 and 15 psig.

(b) Clean turbine housing scroll

using solvent P-D-680, Type II or equiv-

alent. Dry with clean, lint-free cloth

or filtered, low pressure compressed

air.

(c) puddle weld to fill rub area

by fusion arc weld using Hastelloy X

filler rod (AMS5798) with gas backup.

(d) Hand finish to blend weld to

flange surface.

(e) perform fluorescent pene-

trant inspection.

Figure 9-17. Repair of Turbine

Housing Scroll

(3) Straighten and correct diam-

eter B out of roundness as follows:

(a) Cold straight diameter B to

(d) Fusion arc weld cracks using

correct out of roundness to within 0.030

Hastelloy X filler rod (AFS4798) with

Use care to prevent metal thin-

inch.

gas backup.

ning.

(b) Perform fluorescent penetrant

(e) Hand finish to blend weld to

inspection.

existing surface.

(See

i. Repair Turbine Nozzle.

(f) perform fluorescent pene-

figure 9-10, item 19.)

trant inspection of weld area.

9-34