TM 55-1730-229-34

TO 35C2-3-473-2

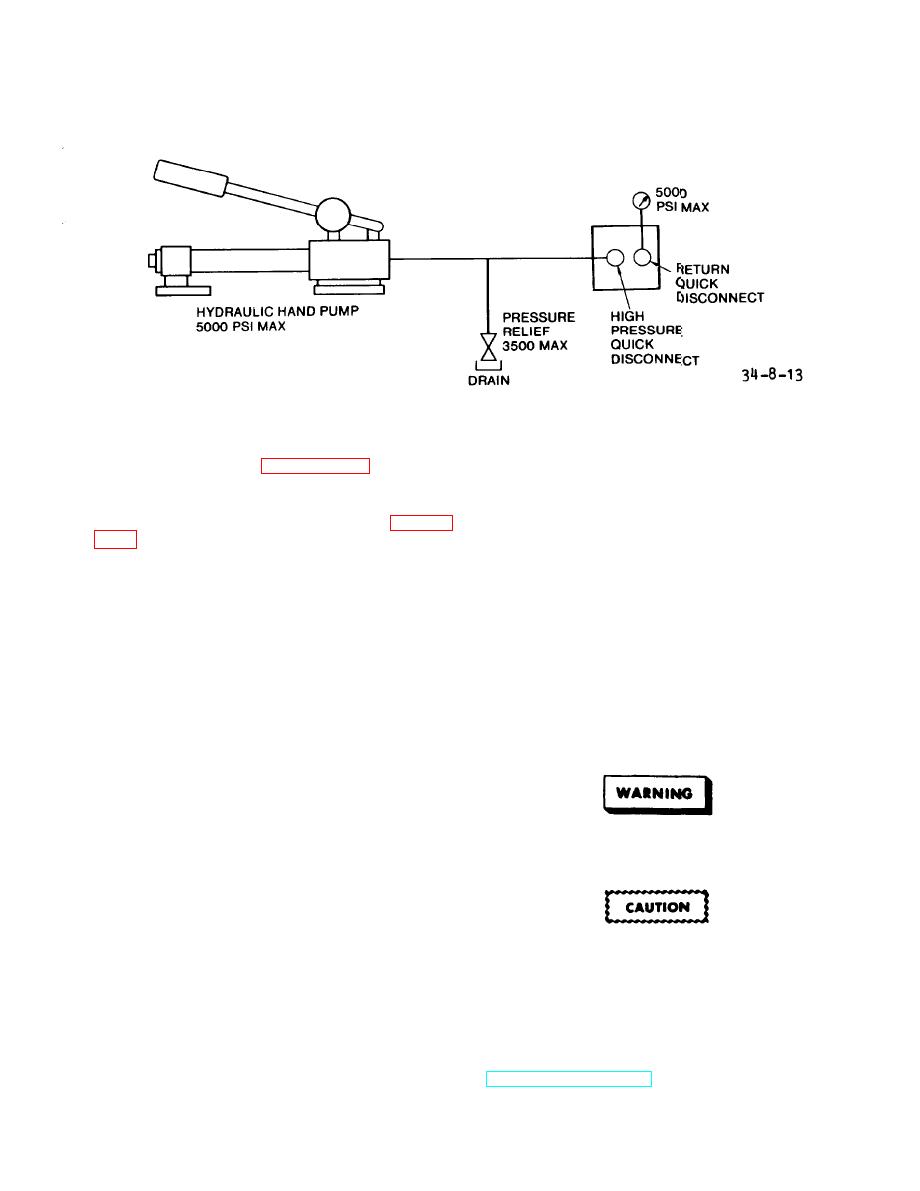

Figure 8-13.

Dual Manifold Test Set-Up

(See figure 8-13.)

return path. Valves and fluid

Test.

d.

ports are provided for filling and

draining hoses.

(1) Connect hydraulic dual mani-

fold to test set-up as shown in figure

(2) Pressurize dual manifold with

hand pump to 3,300 psi and let set for

1/2 hour with no change on gauge. Look

NOTE

for external leaks. If no leaks, remove

The single input is branched to

drain port cap. Open drain/fill valve.

Release pressure and disconnect test

two equal output lines and two re-

turns are combined into a single

set-up.

Section III.

MODULE DISASSEMBLY

8-16.

DISASSEMBLY.

8-15. INTRODUCTION. This

section

contains the procedure for total disas-

sembly of the hydraulic module. To gain

access to, remove, and re-install cer-

Insure Hydraulic System is not

tain components the module must be to-

under pressure before starting

With some small

tally disassembled.

work on Hydraulic System.

variations, there is essentially only

one possible sequence for disassembly

(and re-assembly) of the module. If the

prescribed sequence is not followed it

will be difficult, if not impossible, to

Always put plastic plugs into con-

nectors and plastic caps over fit-

gain access to and torque hydraulic fit-

tings upon disconnection. This

tings during re-assembly.

protects threads and prevents con-

tamination.

a. Drain fluid from hydraulic module

as described in paragraph 3-9.d. of

TM 55-1730-229-12.

Change 5

8-25