TM 11-6130 -243-14-3

refinishing practices specified in TB 430118. Refer

d. Clean the front panel, meters, and control

to SB 11573 for supplies available for field painting

knobs; use a soft cloth. If necessary, dampen the cloth

and preservation.

with water; mild soap may be used for more effective

cleaning.

39. General Troubleshooting Information

3-8. Touchup Painting Instructions

Troubleshooting the power supply is based upon the

operational check contained in the preventive

NOTE

maintenance checks and services daily schedule (para

Touchup painting recommended instead of

refinishing whenever practical;

all functions starting with Item #5 in the preventive

screwheads, binding posts, receptacles,

maintenance checks and services daily schedule (para

and other plated parts will not be painted

or polished with abrasives.

mal indication or result is observed; note the item

number in the troubleshooting chart (para 3 11). If

Remove rust and corrosion from metal surfaces by

the corrective measures indicated do not result in cor-

lightly sanding them with fine sandpaper. Brush two

rection of the trouble, higher category maintenance is

thin coats of paint on the bare metal to protect it from

required.

further corrosion. Refer to applicable cleaning and

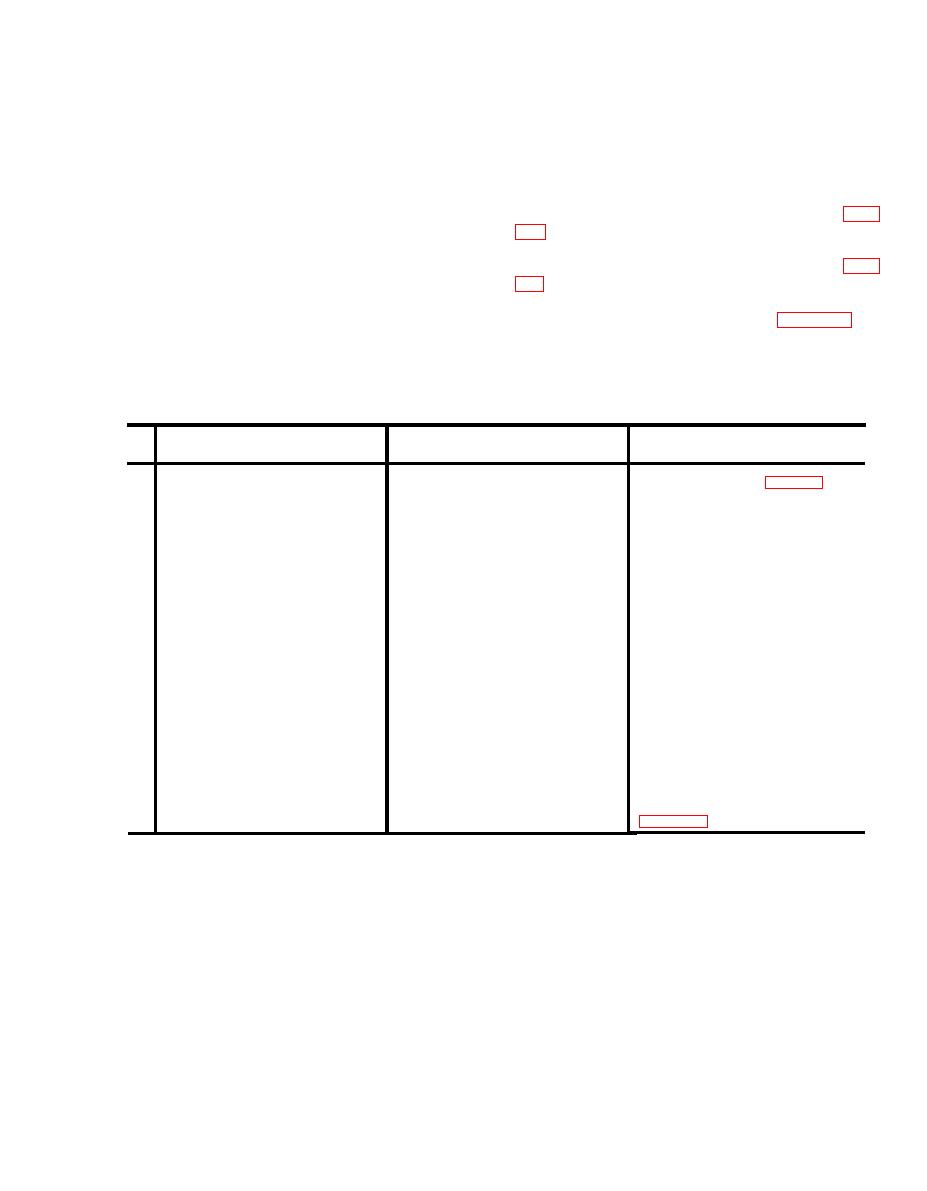

3-10. Troubleshooting Chart

Item

Checks and Corrective

Trouble Symptom

Probable Cause

No.

Measures

1

PILOT LIGHT does not light

Defective PILOT LIGHT

Replace indicator lamp (para 3 11 )

a. VOLTS meter indication does not

a. VOLTS meter is defective or OUTPUT

2

a. Higher category maintenance is re-

vary in accordance with changed

VOLTAGE ADJUST switch is shorted.

quired.

settings of OUTPUT VOLTAGE

ADJUST switch.

b. AMPS meter indicates zero at all

b. AMPS meter is defective or AM-

b. Higher category maintenance is re-

quired.

times.

METER SWITCH is open.

3

With CIRCUIT BREAKER switch set

Short circuit across CIRCUIT BREAKER

Higher category maintenance is required.

to OFF, VOLTS meter or AMPS meter

switch.

does not indicate zero, and PILOT

LIGHT does not extinguish.

Inspect cable insulation. With power dis-

4

Cable insulation cuts, burns, abrasions,

Defective cable or cables.

connected and CIRCUIT BREAKER

or pinch marks that could cause short

switch ON, check continuity between any

circuits or open circuits.

two input power leads with Multimeter

than 5 ohms. Check continuity between

ground lead on input cable and cart

chassis with multimeter. Resistance

should be less than 5 ohms. Check con-

tinuity between two output leads with

multimeter. Resistance should be less

than 5 ohms. If necessary, replace cables

(paras 3-12 and 3-13.)

b. Loosen the input cable strain relief by rotating

3-11. Replacement of Indicator Lamp

the outer cover counterclockwise.

a. Turn t h e glass i n d i c a t o r lamp jewel

c. Remove the four screws attaching the input

counterclockwise and pull it out to expose the defec-

cable to the input filter.

tive lamp.

d. Remove the input cable.

b. Press in on the indicator lamp and turn it

e. Replace the cable.

counterclockwise to unlock it.

f. Reassemble the power supply by reversing steps

c. Pull the defective indicator lamp out and replace

c through a above.

it with a new one. Push the indicator lamp in and

twist clockwise to lock it,

3-13. Replacement of Output Cables

a. Remove top cover from power supply by

3-12. Replacement of Input Cable

removing the four cover screws.

a. Remove top cover from power supply by

b. Loosen the two output cable strain reliefs by

removing the four cover screws.

rotating the outer covers counterclockwise.

3-3