TM 11-6130-266-15

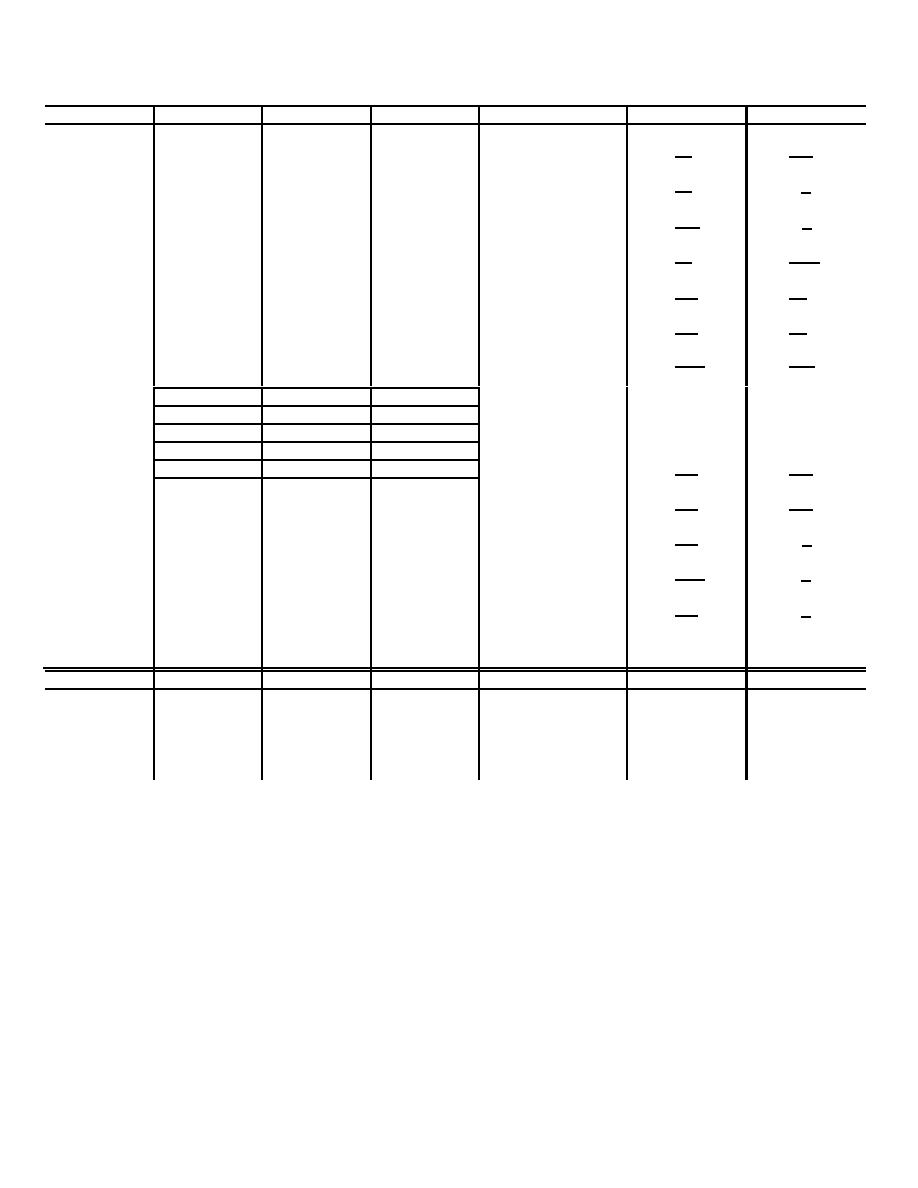

Ref des

VE

VB

VC

Voltage ref pt

RRE

RBC

A1Q8

+12.0

+11.2

+3.0

Pin 17

1K

950

2K

10K

A1Q9

+2.2

+3.0

+2.6

Pin 17

4K

∞

880

800

A2Q1

+1.0

+1.70

+10.0

Pin 8

30K

∞

900

825

A2Q2

-0.1

-0.7

-19.0

Pin 3

1K

1.1K

4K

∞

a

A2Q3A

+8.8

+9.1

+13.0

Pin 2

800

9K

1.1K

1K

a

A2Q3B

+8.5

+9.1

+15.0

Pin 2

800

7K

1.1K

950

A2Q4

0.0

0.0

+16.0

Pin 2

1.1K

10K

800

800

b

A2A1

V2

V3

V4

Pin 2

0.0

0.0

-16.0

Pin 2

--

--

V5

V6

V1

Pin 2

--

--

-15.0

-5.2

+16.0

Pin 2

--

--

e

A3Q5

0.0

0.0

32.5

A8C2 (-)

100

200

100

200 (d)

e

A3Q6

0.0

0.0

32.5

A8C2 (-)

100

200

100

200 (d)

A5Q1

0.0

0.0

+15.5

Pin 14

950

∞

800

800

A5Q2

0.0

0.0

+15.5

Pin 14

3.8K

∞

900

800

A5Q3

0.0

-0.05

+32.5

Pin 8

400

∞

400

800

SCR's only

Gate

Cath

Anode

Voltage ref pt

RGK

RAK

A4Q1

-0.25

0.0

-32.5

A4A2P1-10

100-1K

∞

100-1K

∞

A4Q2

-0.25

0.0

-32.5

A4A2P1-10

100-1K

∞

100-1K

∞

a A2Q3A and, A2Q3B are in 1 case

b Resistance data not valid

c RBE and RBC measurements made with A3 in circuit

d Voltage is average of square wave

e SCR voltages are waveform averages

isolating transformer between the iron the line. Use a

5-9. General Parts Replacement Techniques

All the parts of the power supply can be replaced without

higher wattage soldering iron for heavier duty soldering.

special procedures. The following precautions apply

specifically to this equipment.

CAUTION

a. Do not disturb the setting of any potentiometer.

Do not use a soldering gun;

b. The power supply is transistorized. Use a

damaging voltage can be induced

pencil-type soldering iron with a 25-watt maxi mum

into components.

capacity. If the iron must be used with ac use an

5-8.2 Change 3