TM 55-1730-229-12

NOTES

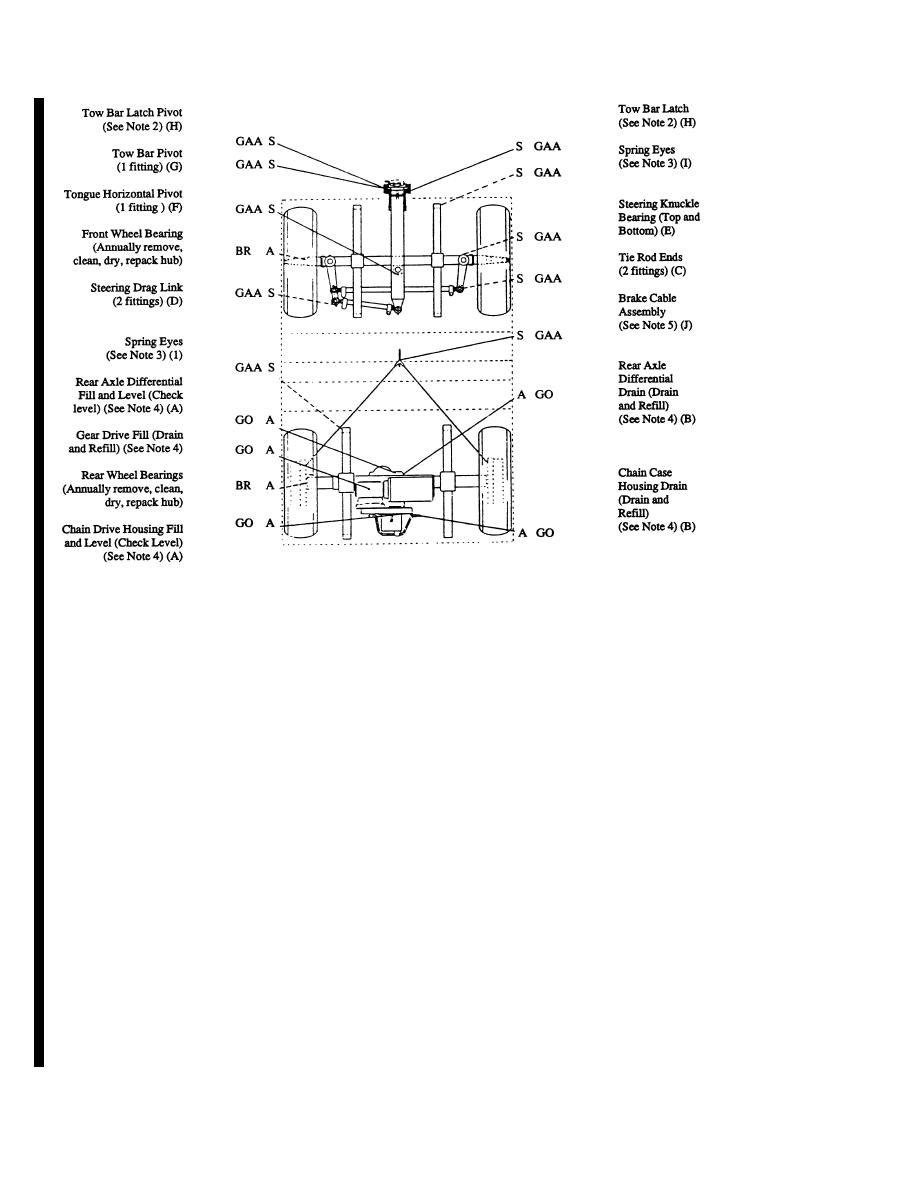

1.

ENGINE GEARCASE AND OIL FILTER. Drain gearcase and replace oil filter semiannually or every 250

engine operating hours, whichever occurs first. Drain only when hot after operation. Inspect magnetic

drain plug and oil filter for metal particles. The presence of metal particles may indicate internal engine

damage. Refill with MIL-L-23699 to full mark on gearcase fill level indicator (2.3 qts). Run engine for 15

minutes and recheck oil level.

2.

TOW BAR LATCH. Semiannualy lubricate tow bar latch lever bearing surfaces sparingly with OE/HDO.

Coat latching surfaces with a thin coat of GAA.

3.

SPRING EYES. Semiannually lubricate spring eyes with OE/HDO.

4.

DRIVE GEARCASES. Drain gearcases annually. Drain only when unit is warm after operation. Check

level at axle differential. Level should be within 1/2 inch of plug opening when cold, and at plug level

when at operating temperature.

5.

BRAKE CABLE ASSEMBLY. Semiannually lubricate brake cable connection points with a thin coat of GAA.

Lubricate brake lever bearing surfaces with OE/HDO.

6.

OIL CAN POINTS. Semiannually lubricate all hinges, latches, and clutch and brake linkages with OE/HDO.

7.

CLUTCH PUSH ROD. Semiannually lubricate. Remove hinge pin and quick release pin from the square rod

clutch level. Move lever away and pull out the push rod until the rubber seal shows. Wipe clean. Coat push

rod lightly with Dow Corning, FSCM 71984 Molykote G-RAPID Spray. Reassemble. Replace cotter pin.

8.

HYDRAULIC SYSTEM. Semiannually drain and re-fill hydraulic reservoir and change both high and low

pressure filters with new type filters 3 and 5 micron. Refill system with MIL-H-83232.

Figure 3-1. Lubrication. (Sheet 2 of 3)