TM

55-1730-229-12

AG

320A0-OMM-000

TO

35C2-3-473-1

TM

1730-12/1

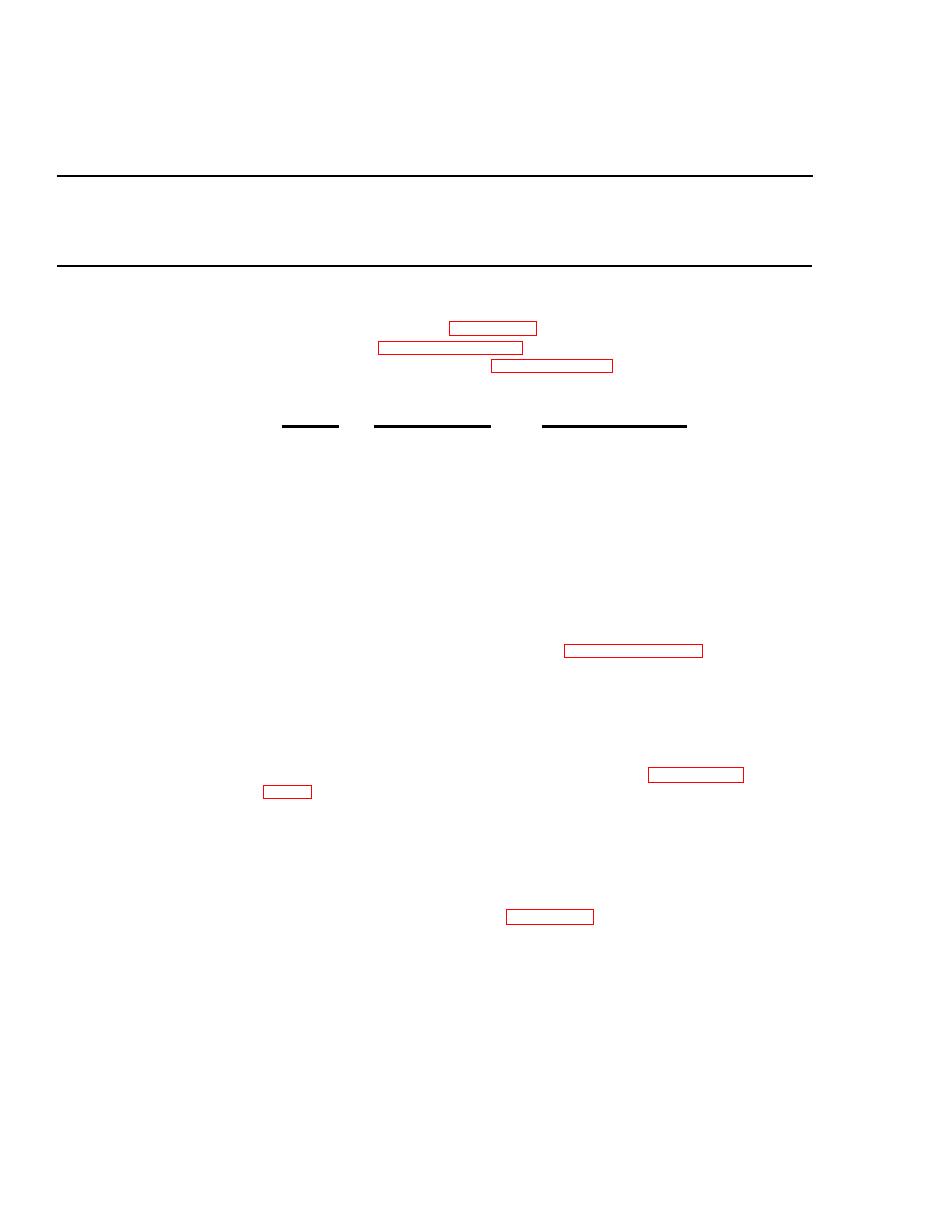

Table 4-2.

Organizational Troubleshooting (continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

84.

(continued)

If any indication in table 4-7 was not normal, remove relay

j.

from socket (paragraph 4-36.b). Check for continuity between

the following points (see FO-3 sheet 1):

Check continuity

If no continuity,

From

To

replace wire no.

J8-P

E3E20

3K2

socket

Xl

J8-B

3K2

socket

X2

E36B20N

J8-L

E25C18

3K2

socket

Al

J8-M

E4B18

3K2

socket

B2

J8-N

E31A20

3K2

socket

B2

J18-B

3K2

socket

B1

L4J18

3K2

socket

A2

E3F20

3K2

socket Xl

If no continuity, replace indicated wire or notify

maintenance supervisor. If all continuity checks good,

replace relay 3K2 with new relay (paragraph 4-36).

BATTERY/CHARGER TRANSFER RELAY AND POWER DIODE MALFUNCTIONS.

85.

Step 1.

Perform this step if the battery/charger transfer relay is suspected

of malfunction.

a. Disconnect battery and lower control panel (paragraph

b.

Open electrical tray access door.

c. Disconnect main harness connectors P9 and P18 from electrical

tray connectors J9 and J18.

d.

Perform tests indicated in table 4-8 for relay in deactivated

state.

NOTE

Two test wires made from 20 gage wire are required for step e.

Each wire should be terminated on one end with a male connector

pin, and a clip on the other end.