TM 55-1730-229-12

AG 32OAO-OMM-000

TO 35C2-3-473-1

TM 1730-12/1

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

Section V.

Determining (PMCS) Intervals.

Organizational PMCS on the AGPU should

a. To ensure that the AGPU is ready

be- performed on a weekly (W) basis,

for operation at all times, it must be

monthly (M) basis, semi annual (S)

inspected systematically so defects may

basis, and per-hour-of-operation

(H)

be discovered and corrected before they

basis as indicated in table 4-1.

The

result in serious damage or failure.

running time meter on the GTE is used to

The necessary preventive maintenance

determine AGPU operating time.

checks and services that are to be per-

formed by Organizational personnel are

d. PMCS for Units in Continuous

listed and described in table 4-1.

Operation. For PMCS performed on an

operating time basis, perform PMCS as

b. Defects discovered during opera-

close as possible to the time intervals

For units in continuous op-

tion will be noted for future correc-

indicated.

Stop operation immediately If a

eration, perform PMCS before starting

tion.

deficiency is noted which would damage

operation if continuous operation will

All deficiencies and

extend service past that which is shown.

the equipment.

short-comings will be recorded together

e. (A, N, MC) Preventive Mainte-

with the corrective action taken on the

nance Checks and Services. Table 4-1

applicable form. Air Force users shall

refer to the applicable Inspection manu-

contains a tabulated listing of PMCS

which shall be performed by Organiza-

als and work card sets in the TO 35C2-3

The item numbers are

series and table 4-1 for detailed pro-

tional personnel.

Marine Corps users should re-

listed consecutively and Indicate the

cedures.

sequence of minimum requirements.

fer to current issue of TM 11275-15/1.

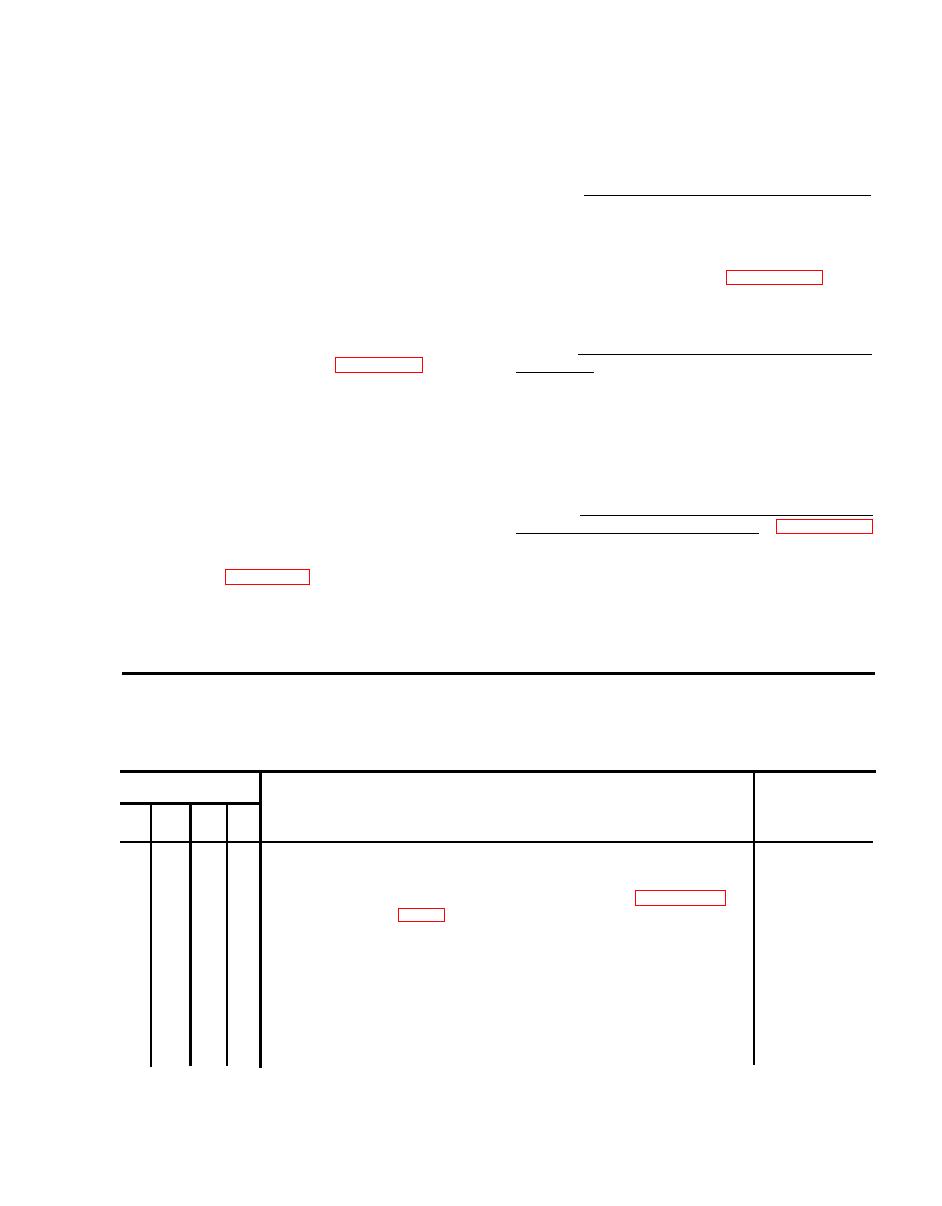

Organizational Preventive Maintenance Checks and Services

Total M/H: 0.3

W

-

Weekly (40 Hrs)

Total M/H: 1.6

M

-

Monthly (100 Hrs)

Interval

Total M/H: 2.6

S

-

Semi Annual (500 Hrs)

H

-

Per-hour-of-operation

Organization

Work Time

H

S

W

M

M/H

Inspection Procedures

CONTROL PANEL AND ELECTRICAL COMPARTMENT

0.2

1

(1) Lower control panel for maintenance (para-

graph 4-24) and inspect control panel wiring

harness for loose wiring connections and

damaged or burned wires.

(2) Inspect components mounted on bulkhead

behind control panel:

(a) Inspect AC and DC main cantactors for

damage or loose connections.