TM 55-1730-229-12

EQUIPMENT CONVERSION.

bracket (7) inside engine compartment (8) by removing

NOTE

four bolts (11).

If hydraulic power is not required for an ex-

(5) Remove drain tube (6) from fitting (10) on

tended period of time, the pump should be

hydraulic pump (4).

disconnected from the GTE. This is done by

installing a spacer between the hydraulic pump

(6)

Lift drain tube (6) up and out of grommet

and the engine/gearcase pad. This discon-

(15).

nects the pump driveshaft from the gearcase

output-saving wear on pump and reducing load

(7) Support hydraulic pump and remove four

on engine.

nuts (3, figure 4-1) and washers (2) that secure pump

on gearcase pad (6).

a. Installation of Hydraulic Pump Spacer. (See

(8) Move hydraulic pump (4) back approxi-

mately four inches.

(1)

Disconnect battery connector from battery.

(2)

Open engine access door.

(3) Remove DC cable from storage compart-

ment and remove hydraulic access cover (figure 4-6).

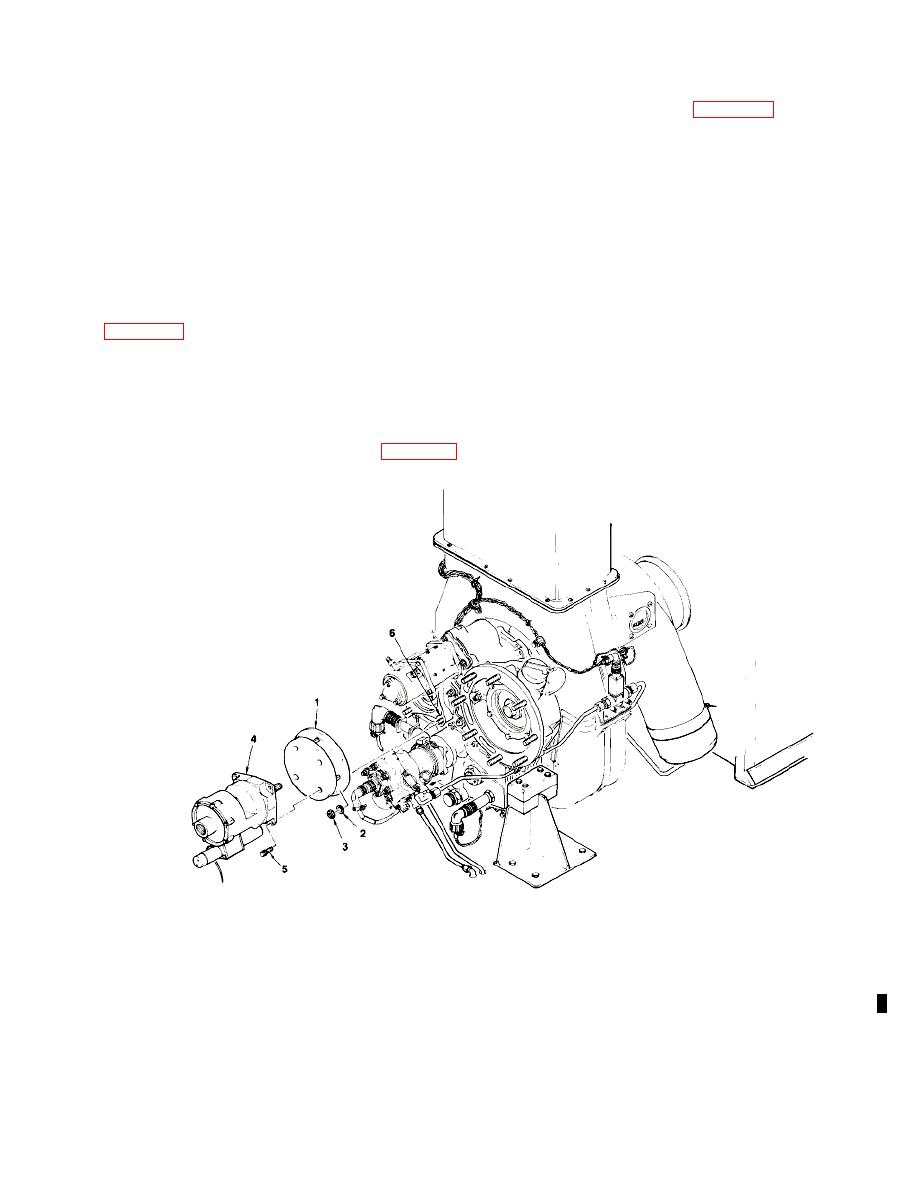

5. BOLT

1. SPACER

3. NUT

2. WASHER

4. HYDRAULIC PUMP

6. GEARCASE PAD

(9) Insert spacer (1) between hydraulic pump

(10) Install four nuts (3) and washers (2) that

(4) and gearcase pad (6). Ensure that flat side of spacer

were removed in step (7). This will attach spacer to

(1) is against the gearcase pad (6).

gearcase pad.