TM 55-1730-229-34

AG 320A0-MME-000

TO 35 C2-3-473-2

TM 1730-34/1

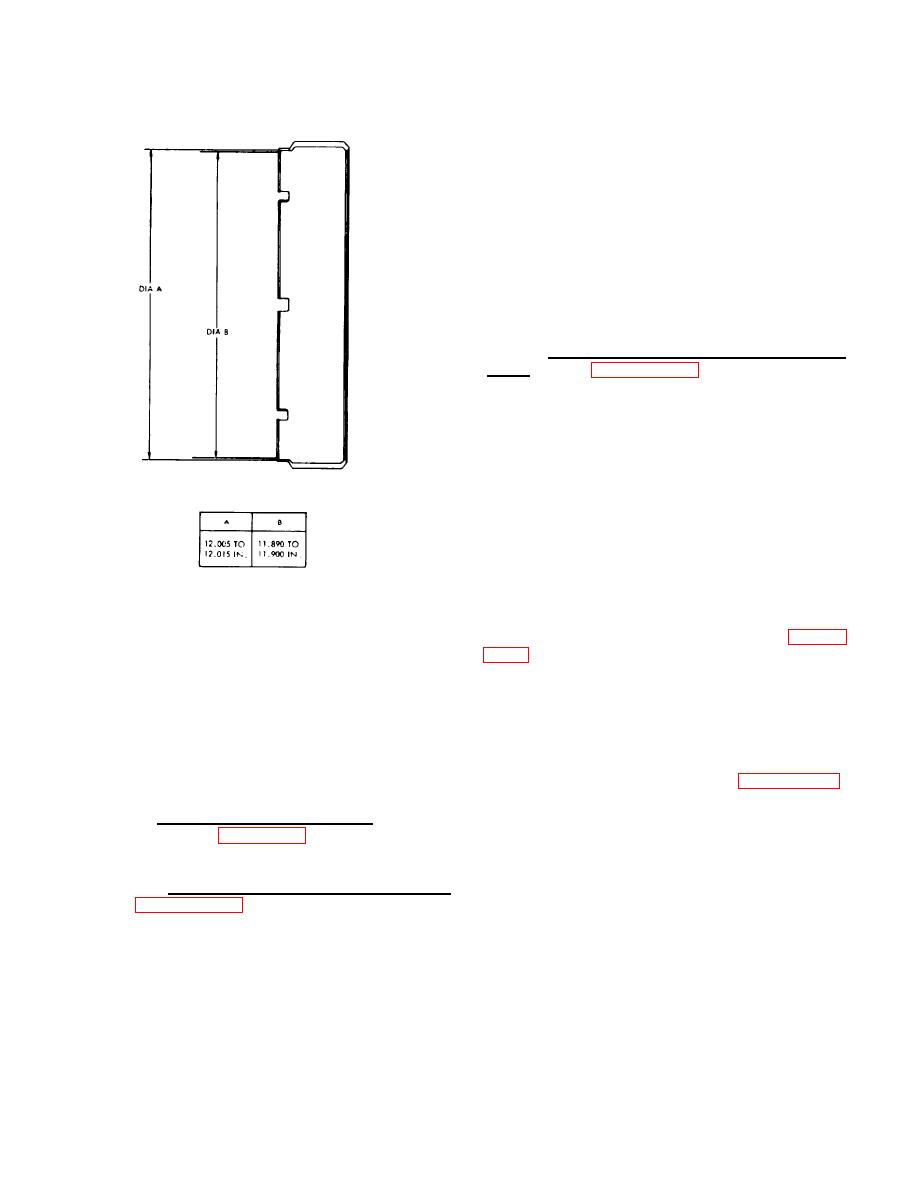

(3) Dimensionally check Diameter

B. Diameter B shall be 11.890 to 11.900

inches. Replace if not as specified.

(4) If damage is evident or sus-

pected perform fluorescent penetrant in-

spection in accordance with MIL-I-6866.

No cracks allowed.

(5) Replace containment ring if

inspection requirements are not met.

d.

Turbine Plenum Assembly Inspec-

(See figure 9-13.)

tion.

(1) Check for damaged or missing

Repair if

plenum assembly nuts (1).

damage is indicated.

(2) Visually check insulation ma-

terial on plenum (2) for damage (bare

metal visible). Repair if damage is in-

dicated.

34-9-12

(3) Check for cracks in plenum

(2). Repair if cracks are indicated.

Figure 9-12. Inspection of

Containment Ring

(4) Check for distortion of ex-

haust pipe portion of plenum (2, figure

Replace turbine plenum assembly

if distortion exceeds 0.125 inch.

(5) Using 291984-1 scroll housing

puller, separate turbine housing scroll

(20) and assembled deflector assembly

(5) Dimensionally inspect Diameter

A. Diameter A shall be 11.840 to 11.846

(17), turbine nozzle (19), shim (18),

inches.

and shim (16) from turbine plenum assem-

bly (21).

(6) Check Diameter A ( figure 9-12)

Diameter should be

for out of round.

b. Inspection and Checks. Perform

round within 0.010 inch.

procedures in table 9-5.

(7) Check Surface B for flatness.

Surface B shall be flat within 0.010

c.

Containment Ring Inspection.

inch.

(See figure 9-12.)

(8) Perform fluorescent penetrant

inspection in accordance with MIL-I-

(1) Visually

containment

check

Refer to Repair if cracks are

ring for cracks and deformation. No

6866.

indicated.

damage allowed.

(2) Dimensionally check Diameter

(9) Replace/repair turbine plenum

A. Diameter A shall be 12.005 to 12.015

assembly if inspection requirements are

inches. Replace if not as specified.

not met.

9-27