TM

55-1730-229-12

AG

320A0-OMM-000

TO

35C2-3-473-1

TM

1730-12/1

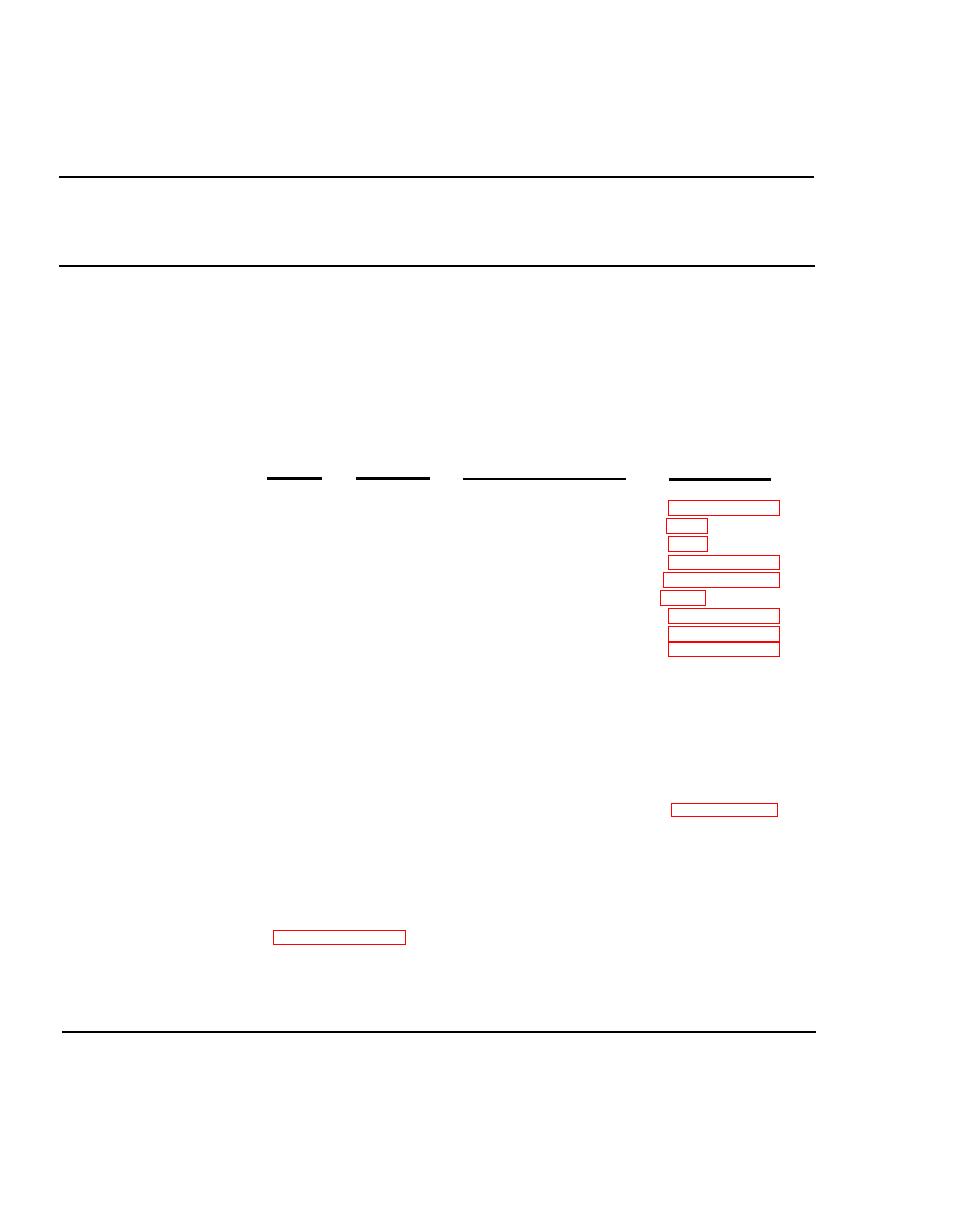

Table 4-2.

Organizational Troubleshooting (continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

(continued)

99.

b.

Use an analog multimeter to check resistance between the

points listed below. The meter should read less than 25 ohms

when the meter is connected with positive lead on connector

pin, and should read greater than 10K ohms when meter is

connected with negative lead on connector pin. If not the

diode or wire is defective.

Measure

If reading not as

From

To

specified, replace

Fig. Ref.

J5-6R

1DS11(+)

1CR9 or wire E21A20

J5-19L

1DS18(+)

1CR11 or wire P15B20

J5-20R

1CR10 or wire P16B20

1DS19(+)

1CR4 or wire X21B20

J7-9L

1DS17(+1

J7-10L

1DS16(+)

1CR3 or wire X22B20

J7-1R

1S5-2

FO-1

1CR6 or wire P4OA20

1DS11(+)

J7-22L

1CR5 or wire X46B20

J7-12L

lDS14(+)

1CR1 or wire X24B20

J7-11L

lDS15(+)

1CR2 or wire X23B20

PRESSURE TRANSDUCER MALFUNCTION

100.

If the pressure transducer is suspected of malfunctioning, test the transducer

as follows.

a.

Disconnect battery.

Disconnect one wire from the transducer (19, figure 4-55).

b.

c. Check resistance between transducer terminals. Resistance

should be approximately 73 ohms with no pneumatic output. If

resistance is not approximately 73 ohms, replace transducer.

d.

Connect battery and operate system with pneumatic output

terminals, then shut down system.

e.

If resistance was not approximately 10 ohms with pneumatic

output, replace transducer.